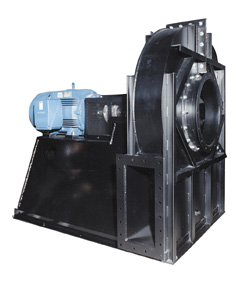

Pressure Air Fans

To meet specific applications, PA fans can be built with stainless steel or alloy construction. Split housings facilitate wheel removal without disturbing connecting ductwork. Integral inlet boxes, pre-spin inlet dampers and opposed-blade outlet dampers all control air flow. Belt guards and shaft coolers are also common options, in addition to the various housing and wheel liners. Chicago Blower engineers are eager to design and build the pressure fan that meets your exact requirements.

Application

Chicago's Pressure Air Fans are at work in as many diverse applications as they are in locations throughout the world. Clean air applications include combustion air, air drying primary air ejectors, and product cooling. This fan can handle pneumatic conveying systems. The PA fan is ideal for corrosive exhaust, air pollution systems and chemical processing. By adding ceramic tile or chromium carbide wheel and housing liners, Chicago's PA fans easily handle abrasive materials. In particular, fans with ceramic tile liners are extremely effective in pulverized coal applications, handling up to 250 grains per cubic feet of air. For corrosive gases, a stainless steel wheel and housing is available, or a lower cost rubber-lined, mild steel housing will often fulfill the requirements.

Operating range

| Maximum CFM |

440,000 |

| Maximum Static Pressure |

108" wg |

| Maximum Temperature |

1000 degree Celcius |

| Fan Sizes |

20" to 100" |

Features

- Designed to meet specific customer performance and mechanical requirements

- All housings are standard with welded construction throughout

|

- Available in arrangements 1, 3, 4, 7, 8, and 9

- Fans are equiped with flanged inlet and outlet, access door, drain, shaft seal, guards for shaft, bearing and couplings, and extended lube lines

|

Options

- Integral inlet box

- Multiple arrangements

- Leak resistant construction

- Various blade liner materials

- Heat treated wheels

- Fan jacking bolts

- Spark resistant Type "C"

- AWS welding

- Wheel balance to G2.5 and lower

- Inlet or outlet dampers

- Belt guard

- Multi-guards

- Isolation springs

- Cooling wheels

- Flanged and valved drains

- Spray nozzles

- Trico oilers with oil level sight glasses

- Speed sensors

|

- Unitary base

- Split housings

- Rubber lined housings

- Scroll and side liners

- Motor jack bolts

- Stainles steel shaft sleeves

- Continuous welding

- API 560 and 673 features

- Companion inlet or outlet flanges

- Quick-clamp or raised bolted access doors

- Shaft cooler

- Evase

- Vibration detectors

- Low leakage seals

- Spacer couplings

- Sleevoil bearings

- Thermocouples or RTDs

|

Alternate Products

Download

Bulletin (1.16 MB)

Bulletin (1.16 MB) Manual (1.35 MB)

Manual (1.35 MB)