Engineering

The need for air is no longer limited to sustaining human life. In this commercial world of intense competition, air has made a striking impact on the efficiency and efficacy of industrial productions. Today, every industry has their specific needs for engineered air, so as to cultivate a perfect environment to work in.

We are outfitted with a pool of specialist in air technology and air engineering, who have excelled in technical skills, along with delivering creative outputs. Our strong in-house team of air engineers is the result of our belief in fostering talents, and incubating them by providing the best of training about the industry, and its technical know-how.

We are the right blend of specialist and age old experience. We have a pool of engineers, working on new product development and customer projects. They have the expertise in air treatment, air filtration, fluid dynamics and heat transfer, hygiene in air treatment and above all, energy efficient systems.

At Draft-Air, we are in the business of perfecting the art of air engineering. Other than having technical finesses, our specialists are well acquainted with the intricate details about the functioning of every customer's industrial processes; also understand the explicit reasons behind all their needs and preferences. This has helped us recognize the applicability of Draft-Air at various stages, and in varying divisions of every project.

So, be it the planning for a suitably engineered air, or consultancy on design of systems for movement of air, or installations with necessary enhancement in areas as optimization of pressure losses maintenance, reduction of noise, or maintenance and after sales services that runs around the clock, and throughout the year, Draft-Air is the one stop solution for all your climate control and air conditioning needs.

Draft-Air & Chicago Blowers use various engineering tools for a precise system design & in-depth designing of a product.

Few of the engineering tools used by Draft-Air

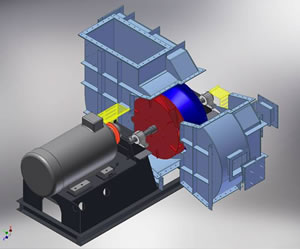

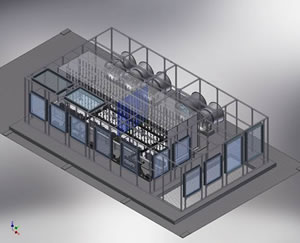

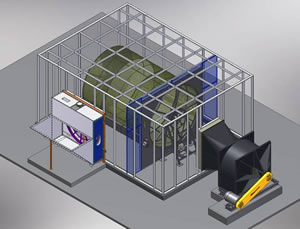

3D Modeling

At Draft-Air all the manufacturing products are 3D modeled which helps in generating part drawing for each components and ensures proper assembly.

Draft-Air has consistently recognized the development and use of modeling tools as a key for success and implementation of optimal solutions that satisfy its client's requirements.

Based on long term experience and backed by numerous industrial references and feedback from operating plants, Draft-Air offers clients its experience in the use of commercially available software, but also in-house developed modeling tools for all aspects of Product & Plant design.

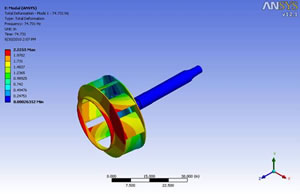

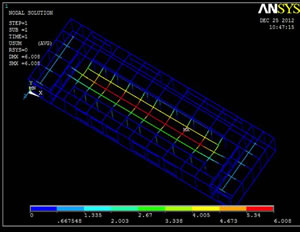

FEA Capabilities

- Critical Speed Analysis

- Torsional Analysis

- Stress Analysis

- Modal Analysis

- Fatigue Analysis

- Failure Analysis

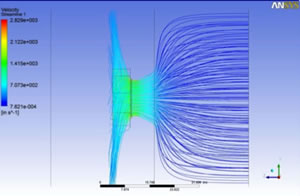

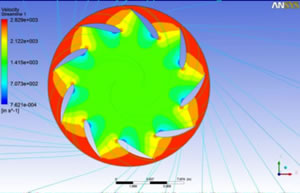

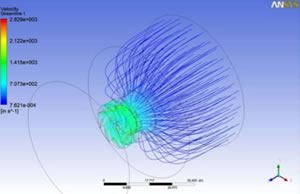

Computer Fluid Dynamics

- Quicker product design cycle

- Improved Performance capabilities

- Increased efficiency

Infrastructure

Draft-Air production facility has a covered area of 50,000 sqft. With 3 main fabrication area called as “High bay” all three high bays have 5 tones EOT crane equipped with state of art machines.

CNC Metal Spinning Machine

Metal spinning machine is used to make Hyperbolic Spun Steel Wheel Cones and Inlet Cones. Draft-Air quality Spun wheel cones optimizes the smooth stable air flow across the entire operating range which add ups to the fan efficiency.

Other areas and applications where we can offer metal spinning components

- Lighting

- Ventilation

- Kitchenware

- Automobile

- Aerospace

- Outsourcing

- Boiler Making

- Defense

- Railroad

- And many others

Features

- One of its kind and size available in India imported from Spain

- Complete CNC

- Can spin Maximum blank diameter up to 2500mm

- Can spin various materials like Carbon Steel, Corten, Domex-700, Weldox, SS-304, SS316, Inconel etc.

- Maximum spinning thickness 14mm in cold spinning

For metal spinning components please send us enquiry to spinning@draftair.com or info@draftair.com.

High Definition CNC Plasma Marking & Cutting Machine

To mark and cut all different profile components of different air handling product.

Some of the key features of our HD CNC Plasma Marking and Cutting Machines are as follows:

- Complete CNC

- Pipe cutting attachment up to 500mm dia.

- Air marking

- Facility to provide Beveling shapes like “v”, “u” etc. on the plates

- Bed size 3000mm in width and 8000mm in length

- Maximum cutting thickness 35mm in plasma source. Oxy cut attachment available to cut above 35mm up to 65mm

- Dust collector is also provided to protect the environment and to increase the working efficiency.

Balancing Machine

Our Schenck balancing machine is capable of balancing 3000mm dia and maximum weight of 5500Kg. Each and every impeller is balanced as per ISO 1940 Gr. 6.3. We can also offer balancing up to Gr 2.5 or lower on request.

We are also equipped with portable balancing machine for field balancing. Our portable field balancing machine is also capable of Bump test/Resonance check.

Airfoil Blade Making Machine

This is Special Purpose Machine (SPM) developed by Chicago Blower Corporation USA same is available with us to make identical Airfoil blades for each size.

CNC Bending & Cutting Machine

Both cutting and bending machine are imported from Greece and have maximum capacity 10mm thick plates.

Above mentioned are few important machines highlighted. Apart from this we also have high end quality MIG and TIG welding machine from Fronius and many other machines. For complete machine list please contact us.

Testing Facility

We have test facility for fan as per following standard

- AMCA 210

- BS 848

- IS 4894